L or Z-Crane? Because not all timber cranes are the same.

Until not so long ago, logs were pulled out of the forest by horses and loads had to be loaded and unloaded by hand. However, when we look back at history, we can see that today we have a powerful crane by our side to help us with tough jobs. However, not all cranes are the same, which is why a distinction is made between the L and Z crane types.

But what is the difference beweteen the L and Z crane?

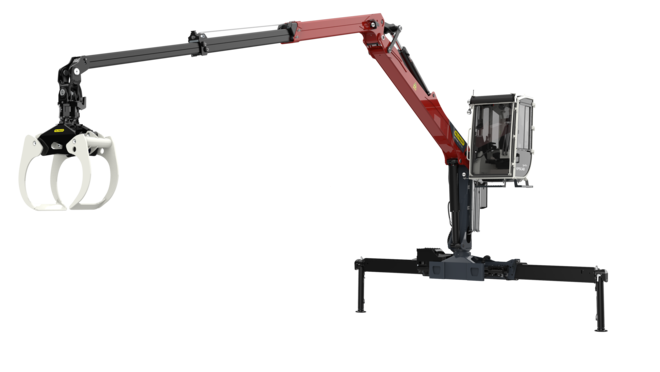

L-Crane

The L-Crane is considered the mother of all timber cranes and is a type of crane that stands out for its excellent work performance. This crane has a long main boom and a shorter knuckle boom, which results in perfect working ergonomics. Due to the longer main boom and the shorter knuckle boom, the main boom needs to be moved less. This has the advantage that the crane operator does not have to control this boom as often and can concentrate on other crane functions.

The L-crane is particularly popular for operations such as rail loading. For example, if wood is taken from the forest once a day and transported to the collection point, the crane only needs to be used for rail loading the rest of the day. Due to this type of operations, the L-crane is more comfortable to drive.

In addition to functionality, comfort and design are also important. The L-crane meets the highest demands in these areas as well, making it a popular type of crane in the timber industry.

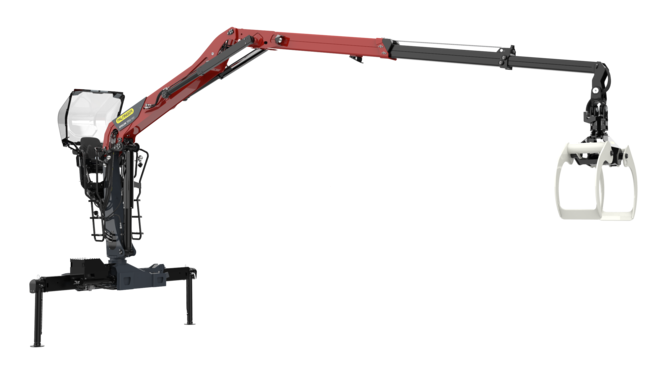

z-Crane

The Z-Crane is the compact brother of the L-Crane and is characterized above all by its compact design, which makes it stand out in direct comparison. In contrast to the L-Crane, where the crane must be laid down on the loading area, the Z-Crane is folded transversely to the direction of travel. This makes it possible to fully load the vehicle up to the legally permitted total height and thus make optimum use of it.

The Z-Crane is frequently used in sawmills in particular. After the logs have been transported to the sawmill, the unloading process takes place in several trips. The compact Z-Crane is particularly advantageous here, as it can work in a confined space and still achieve a high work output.

Overall, the Z crane is a practical solution for use in limited spaces. The compact design and the ability to fully load the vehicle make it an efficient working tool in the timber industry and other areas with limited space.